Illuminate Your Business’s Exterior Elegantly With Advanced Parking Lot Lights

Many businesses struggle with dark and uninviting parking lots at night. LED parking lot lights have emerged as a solution to this problem. This article will guide you through selecting the best lighting for your business’s exterior, focusing on safety, efficiency, and aesthetics. Light up your space effectively! Key Takeaways Benefits of Using LED Parking […]

The Future of Fleet Charging With the Right EVSE Choice

With the number of electric vehicles on the road expected to soar into the millions in the next decade, the need for quality EVSE systems in commercial settings has never been more pressing. The transition to electric fleets presents a unique set of opportunities and challenges. The right EVSE choice ensures the seamless operation of electric […]

Ensuring Continuous Operations with Robust Battery Backup Systems

Power outages in a commercial setting aren’t just inconveniences; they’re potential financial disasters. Imagine a scenario in a bustling industrial facility: machines halt mid-operation, critical data gets lost, and hours of productivity vanish in an instant. This is the reality for businesses without a reliable backup electricity solution. The culprit? Inadequate power supply systems that […]

When and Why You Might Need An Emergency Electrician

Dimming lights, buzzing outlets, and tripped breakers. These are all electrical worries that can interfere with business continuity. These seemingly minor issues can signal serious problems, jeopardizing your property, employees, and customers. Don’t wait for a blackout! Calling an emergency electrician can help eliminate safety risks, minimize downtime, and ensure your business continues to thrive. Take a […]

Electrical Troubleshooting: The Ultimate Homeowner’s Guide

Each year in the U.S., electrical faults cause over 28,000 house fires. While some electrical problems need professional attention, understanding basic electrical troubleshooting can help. You can identify minor electrical issues before they turn into dangerous situations. Have you ever experienced electrical issues in your home? The issue might be flickering lights or buzzing outlets. It […]

Why Electrial Inspection Is Non-Negotiable for Commercial Building Safety

In 2021, 116,500 non-residential building fires caused 1,025 injuries, 115 deaths, and $3,697,200,000 in dollar loss. As a business owner, you should think about the potential impact of fires on your operations. Regular electrical inspections can help to reduce your safety risk exposures.

An electrical inspection checks the property’s electrical system to determine its condition. It aims to protect people and property against potential electrical hazards. It also strives to ensure compliance with local, state, and federal regulations.

Here are various reasons to schedule electrical safety inspections for your commercial building.

Ensure Building Safety

Electrical safety does matter to people who frequent your business. This includes employees, customers, suppliers, and vendors.

If someone to whom you owe a duty of care suffers an electrical injury, they may sue your business. This can result in huge payouts, which may affect a business’s bottom line.

Regular inspections help find and fix electrical issues that cause accidents and injuries. This helps ensure employee safety and the safety of other building users. Fewer workplace injuries translate to reduced liability risks for your business.

Prevent Fires

Acquiring a commercial property requires significant financial investment. That’s why you should protect your investment property at all costs as a business owner.

Having fire insurance is a smart way to protect your business against fires. However, your insurance company will investigate any fire incidents before processing your claim.

If they find that a business fire was a result of negligence, they may reject your claim. This can result in significant financial loss or even business closure.

Routine electrical inspection can help with your fire damage claim. This is because you can show proof of electrical maintenance to rule out neglect as the cause of the fire. Some common causes of fire in commercial buildings include:

Frayed wiring

Faulty switches and outlets

Aging appliances

Defective lighting fixtures

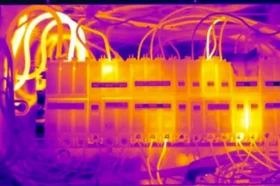

Routine inspections will help prevent loss from electricity-related fire damage to your property. You can also reduce financial losses due to disruptive work events. Modern electricians use advanced inspection tools like infrared thermography to troubleshoot issues.

Improve Employee Retention

Money isn’t the only thing employees think about money when choosing jobs. Safety matters too. Safe workplaces mean fewer accidents, happier employees, and lower turnover rates.

Doing regular electrical inspections shows employees that you care about their safety. This can help your company keep its top talent longer. When employees feel valued and secure, they are more likely to stay loyal and committed to the company’s mission.

Extend the Life of Your Electrical System

Your commercial electrical system costs a significant amount of money to install. As a building owner, you want to protect this investment. One way to achieve this is to invest in preventative electrical maintenance.

Electrical inspections can enhance the reliability and durability of your business electrical system. These inspections will help catch potential issues that could damage your electrical infrastructure.

Early problem detection allows for timely repairs. This keeps your electrical system running well for as long as possible.

Save Money on Future Repairs

Electrical repairs are an inevitable part of building maintenance. And the total costs can add up fast depending on the type and severity of electrical issues involved. Unnoticed issues lead to higher repair costs.

Electrical inspections allow you to catch electrical faults early. This helps prevent them from causing bigger problems over time. This can help avoid expensive repairs or replacements in the long haul.

Increase Employee Productivity

About 2 in 5 employees were away from work for more than one full week due to nonfatal electrical injuries. 21 percent of these victims missed work for 31 or more days.

If electrical hazards remain unaddressed, your workers can get injured on the job. These injuries can cause them to miss work. A high absenteeism rate will affect employee productivity, slowing down business growth.

With frequent electrical inspections, you can reduce potential electrical hazards at work. This will help reduce the causes and costs of absenteeism.

Ensure Your Building Is Up to Code

Every business must follow building safety regulations. Non-compliance can result in:

Hefty fines and penalties

Loss of business reputation

License revocation

To stay compliant, get regular electrical inspections by a qualified commercial electrician. They’ll help you meet National Electric Code (NEC) standards and building safety requirements.

Improve Your Company’s Reputation

A commitment to safety enhances a company’s reputation. Different stakeholders care about your business reputation for different reasons. For example:

Government agencies expect you to run a compliant business operation

Employees want to work for companies that value workplace safety

Customers want to transact with a company that has a positive brand image

By conducting frequent electrical safety inspections at work, you can decrease safety issues. A good business safety record shows your prowess at mitigating safety risks. This will enhance your brand image and increase the business’s growth potential.

How Often Should You Perform Electrical Inspections?

Every business operation has unique electrical needs. Therefore, the frequency of electrical inspections can vary from business to business. Some of the factors that can influence the how often you should inspect your electrical system include:

The nature of your business

The size of your business building

Industry best practices

Types of electrical equipment used

State and local building laws and regulations

Use a qualified commercial electrician to determine how often you need electrical inspections. They can assess your electrical needs and suggest the perfect electrical maintenance regimen.

Are You Ready to Schedule an Electrical Inspection for Your Business?

Electrical problems can pop up at any time. If left unaddressed, they can exacerbate and cause significant issues down the road. An electrical inspection helps tackle these minor issues before they get out of hand.

This will help you avoid costly repairs and replacements in the future. It also provides peace of mind knowing your business meets electrical safety requirements.

At Houston Electric, we offer a wide array of services to cater to your growing business needs. If you want to ask a question or request a quote, get in touch with us today. Whatever your electrical needs, trust us to deliver exceptional service at great prices.

Infrared Thermography Vs. Traditional Inspection Methods

Unsure about the best method of electrical inspection for your property? Infrared thermography has emerged as a game-changer in this field, outperforming traditional methods with its unique advantages.

Our blog post delves into the differences between infrared thermography and conventional inspections, highlighting how each works and which one might be more suitable for you. Intrigued? Let’s get electrified!

Traditional Inspection Methods

Traditional inspection methods involve visual inspections and manual testing to identify electrical issues. These methods include checking for loose connections, inspecting wiring, and using specialized tools like multimeters to measure voltage and current levels.

However, these methods have limitations in terms of accuracy and efficiency.

What Are Traditional Inspection Methods?

Traditional inspection methods primarily focus on visual checks and use a range of instruments to test electrical systems. Common tools like multimeters, voltmeters, clamp meters, and insulation testers are often employed in these regular inspections.

Inspectors physically survey the equipment for signs of overheating, corrosion, vibration anomalies or unusual noises every three months for high criticality systems and every six months for less critical systems.

They then compare their findings to predetermined safety standards to assess if the system is working within acceptable parameters. Such routine inspections aim at preventing failures or mishaps by identifying potential issues early on.

However, they require a considerable amount of time and resources due to their extensive nature; ultimately making them less efficient when dealing with large-scale operations or complex electrical setups.

Limitations Of Traditional Inspection Methods

Traditional inspection methods, while dependable, exhibit some critical limitations. Firstly, these methods often necessitate the dismantling or physical touch of the systems under inspection. This process is not only time-consuming but also expensive and potentially risky to the inspector.

Secondly, they might fail to identify internal or hidden electrical issues as their detection ability is limited to visual scans and checks. This kind of oversight can lead to unrecognized faults which, in turn, could result in serious complications down the line. Moreover, the results generated from traditional inspections are heavily dependent on human interpretation and hence prone to error.

Lastly, these methods cannot provide real-time monitoring of electrical systems. They simply give a one-time report without an ongoing assessment capability. As compared to infrared thermography that offers continuous monitoring, this is a significant disadvantage.

Infrared Thermography Inspection

Infrared thermography is a non-contact method used to detect and visualize temperature variations in electrical systems.

What Is Infrared Thermography?

Infrared thermography is an efficient technique that leverages thermal imaging equipment. This unique approach spots anomalies in electrical installations, potentially forestalling a failure or dangerous fire.

Technicians perform infrared thermography inspections with advanced infrared cameras specifically designed to scan the surface of components and keep track of changes in temperature.

Cold or hot spots on the thermographic images typically signal defects in the electrical system. It’s worth noting that this method, recognized by the American Society for Testing and Materials, is nondestructive – meaning it won’t cause any harm to your systems.

Plus, it plays a crucial role in electrical predictive maintenance thanks to its ability to preemptively identify problems.

Advantages Of Infrared Thermography Inspection

Infrared thermography inspection offers several advantages over traditional inspection methods:

Detects hidden problems: Infrared thermography can identify electrical issues that are not visible to the naked eye. It can detect heat-related problems such as loose connections, overloaded circuits, and faulty components.

Noninvasive testing: Unlike traditional methods that require physical contact with electrical equipment, infrared thermography is a noninvasive testing method. It uses infrared cameras to measure surface temperatures, making it safe and efficient.

Early detection of hot spots: Infrared thermography can help find hot spots caused by defects in connections and components. By detecting these hot spots early, potential failures and fires can be prevented.

Cost-effective maintenance: Regular infrared thermography inspections can prevent breakdowns and fires in electrical installations, saving businesses from costly repairs and downtime. It is a cost-effective way to ensure the safety and reliability of electrical systems.

Quick and efficient: Infrared thermography inspections are quick and efficient compared to traditional methods. The use of infrared cameras makes it possible to scan large areas in a short amount of time, allowing for swift identification of any anomalies or issues.

Enhances safety: By identifying potential hazards before they cause accidents or fires, infrared thermography inspections enhance the overall safety of electrical systems. This proactive approach helps protect both personnel and property from harm.

Comparison of Infrared Thermography vs. Traditional Inspection Methods

Infrared thermography offers greater accuracy, efficiency, cost-effectiveness, and safety compared to traditional inspection methods.

Accuracy and Efficiency

Infrared thermography offers a high level of accuracy and efficiency when it comes to electrical inspections. By using thermal imaging technology, it can detect hidden issues that traditional methods may miss.

This means that potential problems can be identified early on, minimizing the risk of equipment failure and costly downtime. In addition, infrared inspections can be conducted while the equipment is in normal operation, eliminating the need for shutdowns or interruptions.

This not only saves time but also increases overall efficiency. With the ability to analyze data collected from these inspections, predictive maintenance programs can be implemented with precision, further enhancing accuracy and efficiency in electrical systems.

Cost-Effectiveness

Infrared thermography proves to be a highly cost-effective option for conducting electrical inspections. Compared to traditional inspection methods, building an inventory for infrared thermography is relatively low in cost, while the long-term benefits it offers far outweigh the initial investment.

Quantitative comparisons can be made between infrared thermography and other methods, such as visual inspection and electrical analysis, to determine their cost-effectiveness in different scenarios.

Companies find that implementing an infrared thermography program not only saves on overall expenses but also helps identify potential issues before they escalate into costly problems.

Infrared thermography inspection offers a high level of safety and a non-destructive approach when assessing electrical systems. Unlike traditional inspection methods that may involve physically accessing equipment or dismantling structures, infrared thermography allows inspectors to detect potential issues without causing any damage.

This means there is no need for invasive procedures or disruption to the system’s operation. With its non-invasive and non-destructive nature, infrared thermography provides a safe and effective method for identifying problems in electrical systems while minimizing risks to personnel and infrastructure.

Conclusion

Electrical inspections have been revolutionized by the advent of infrared thermography, surpassing traditional methods in accuracy, efficiency, and safety. With its ability to detect potential electrical issues early and its cost-effective approach in the long run, infrared thermography stands out as a non-destructive and reliable solution. Recognize the essential nature of this innovative technology and safeguard the efficiency of your electrical systems. Trust in Huston Electric, Indiana’s leading electrical service provider, to harness the full potential of infrared thermography and ensure optimal safety across all your facilities.

Infrared Thermography Vs. Traditional Inspection Methods (FAQs)

What is infrared thermography?

Infrared thermography is a technique used in electrical inspections to detect heat emissions, which can indicate potential problems.

How does infrared thermography differ from traditional inspection methods?

Unlike traditional inspection methods that focus on visual or physical examinations, infrared thermography uses cameras to capture heat patterns and temperatures unseen by the naked eye.

Can Infrared Thermographic Inspections replace Traditional Inspection Methods?

While infrared thermography provides valuable and unique insights, it should be used as a supplement rather than replace traditional full-scale inspections for comprehensive results.

Are there specific situations where Infrared Thermography would be more advantageous?

Yes, especially when inspecting large areas or systems with intricate wiring; being non-invasive and able to quickly identify hotspots makes it an efficient choice.

Modern Alternatives To The Federal Pacific Panel

Do you have a Federal Pacific Panel at your home or business property? If so, you must be aware that despite their once popular status, these panels can pose potential safety threats.

This post will shed some light on the pitfalls of continuing to use Federal Pacific Panels and offer modern, safer alternatives—ensuring peace of mind when it comes to electrical safety.

Read on, as we make electricity more reliable and secure for everyone!

The Issues with Federal Pacific Panels

Federal Pacific panels have been a source of controversy and concern due to their faulty circuit breakers, which have been known to fail in protecting against electrical overloads and short circuits.

Overview Of Federal Pacific Panels

Federal Pacific Electric Company manufactured Federal Pacific panels extensively from the 1950s to the 1980s, gaining popularity owing to their cost-effectiveness and claimed reliability.

Homeowners found them appealing during this period, and they were installed in numerous residential properties across America. These panels contained circuit breakers designed to cease electrical flow when an overload or short-circuit occurred.

However, these panels are now considered problematic due to various design flaws like inadequate gutter space and faulty wire connections that violate current safety codes. Notably, investigations have exposed a significant risk of fires linked with defective circuit breakers within these panels.

The Problems Associated With Federal Pacific Circuit Breakers

Federal Pacific circuit breakers, specifically their Stab-Lok line, present a significant fire risk due to high failure rates. These panels have been found to malfunction at an alarming rate – around one-third of tested units displayed some sort of potentially dangerous defect.

This flaw can lead to a catastrophic failure where the breaker fails to ‘trip’ or shut off during an overload or short circuit situation, causing overheating and potentially sparking a fire.

Despite its risk, remember that not every Federal Pacific panel is hazardous; the major concerns lie within the Stab-Lok brand. It’s this unforeseen threat that makes these 200-amp Main Lug Panels so problematic and it reinforces why many experts recommend replacing your Federal Pacific panel altogether with safer options such as Square D Panels, Eaton/Cutler-Hammer panels or even Leviton Load Centers which provide advanced technologies like AFCI and GFCI Breakers for improved safety standards in homes and commercial properties.

Alternatives to Federal Pacific Panels

There are several alternatives to Federal Pacific panels, including Connecticut Electric circuit breakers and other compatible replacement options.

Connecticut Electric Circuit Breakers

Connecticut Electric circuit breakers offer a reliable and safe alternative to problematic Federal Pacific panels. These UL-approved alternatives fit seamlessly into existing Federal Pacific setups, ensuring easy replacement without any issues.

Offering a wide choice of replacements, Connecticut Electric goes the extra mile by maintaining competitive prices for various breakers that homeowners and property managers are looking for.

Most importantly, these circuit breakers align with modern safety codes; they incorporate advanced safety features meeting today’s standard requirements. Choosing Connecticut Electric replacements means opting for peace of mind – knowing your electrical system is secure and up-to-date even if you can’t afford complete panel replacement right away. Siemens Electrical Panels Siemens is another highly recommended alternative for those considering moving away from Federal Pacific panels. Known for their quality engineering and safety features, Siemens panels adhere to strict industry standards. These panels are equipped with advanced technologies like AFCI and GFCI breakers, offering added layers of protection against electrical fires and shocks. Furthermore, Siemens offers a variety of panel options to suit both residential and commercial needs, making it a versatile choice for any property.

Other Compatible Replacement Options

There are several compatible replacement options available for Federal Pacific panels. Consider the following alternatives:

Connecticut Electric circuit breakers: These UL-approved breakers are designed to be direct replacements for Federal Pacific circuit breakers. They provide reliable performance and can easily fit into existing panels.

Square D Panels: Square D offers a range of electrical panels that are compatible with Federal Pacific panels. These panels are known for their durability and safety features, making them a popular choice among homeowners and property managers.

Eaton/Cutler-Hammer Panels: Eaton offers a variety of panel options that can replace Federal Pacific panels. These panels are designed to meet strict industry standards and provide reliable electrical distribution.

Leviton Load Centers: Leviton load centers are another viable option for replacing Federal Pacific panels. They offer a wide range of customizable configurations and come with built-in safety features like AFCI and GFCI breakers.

GE Electrical Panels: GE offers a selection of electrical panels that can serve as suitable replacements for Federal Pacific panels. These panels are known for their quality construction and innovative design.

Residential Service: An Effective Alternative to Federal Pacific Panels

Residential service is a highly effective alternative to Federal Pacific panels. These modern electrical systems offer safer and more reliable performance, addressing the issues associated with Federal Pacific Electric (FPE) panels.

With residential service, homeowners can ensure that their homes are protected from electrical fires caused by faulty breakers or panel failures. By replacing the entire panel instead of just the breakers, homeowners can have peace of mind knowing that their electrical system meets current safety standards.

Insurance companies may also be more willing to provide coverage for homes with residential service, as it eliminates the fire risks associated with Federal Pacific panels. Upgrade your electrical system today and enjoy a safer and more secure home environment.

Considerations for Replacing Federal Pacific Panels

When replacing Federal Pacific Panels, it is important to consider factors such as the panel’s amperage, compatibility with existing wiring, and the availability of AFCI and GFCI breakers.

Choose an alternative panel that meets your specific electrical needs and ensure a smooth transition by consulting with a professional electrician.

The Importance Of Replacing The Panel

Replacing the panel is crucial for homeowners and property managers with Federal Pacific panels. Insurance companies refuse coverage for homes with these panels due to their association with electrical failures and fire hazards.

Not replacing the panel can lead to overheating of wiring, electrical overload, and increased risks of fires. Additionally, Fannie Mae requires the replacement of Federal Pacific panels for loan approval.

It’s essential to prioritize safety by choosing an alternative panel that meets your needs and ensures a reliable electrical system.

Factors To Consider When Choosing An Alternative

When choosing an alternative to a Federal Pacific panel, there are several factors to consider. These include:

Compatibility: Ensure that the alternative panel is compatible with your electrical system and meets the necessary specifications.

Safety Features: Look for panels that have built-in safety features such as AFCI and GFCI breakers to protect against electrical fires and shocks.

Quality and Reliability: Choose a reputable brand known for producing high-quality and reliable electrical panels, such as Square D, Eaton/Cutler-Hammer, Leviton, or GE.

Capacity: Consider the capacity of the alternative panel in terms of amperage (200-amp is common for residential use) to ensure it meets your property’s electrical needs.

Cost: Compare the cost of replacing the Federal Pacific panel with the potential income loss from higher insurance premiums due to its safety risks. Get quotes from licensed contractors for an accurate estimate.

Conclusion

There are several modern alternatives to the Federal Pacific Panel that homeowners and property managers can consider. Square D, Cutler Hammer, General Electric (GE), and other brands offer compatible breakers that can replace Stab-Lok breakers found in Federal Pacific Panels.

It is crucial to be aware of the safety concerns associated with Federal Pacific Panels and choose a safer alternative for electrical systems.

Modern Alternatives To The Federal Pacific Panel (FAQ)s

What are the modern alternatives to the Federal Pacific panel?

The modern alternatives to the Federal Pacific panel are up-to-date, safer Main Breaker Panels available in today’s market.

Are main breaker panels reliable compared to the Federal Pacific Panel?

Yes, Main Breaker Panels have shown improved reliability and safety features over Federal Pacific Panels.

How do I choose a good alternative for my old Federal Pacific Panel?

Choose an updated Main Breaker Panel that fits your power needs and has strong safety measures – always look for professional guidance when making a choice.

Is it necessary to replace my old federal pacific panel with a modern main breaker panel?

Yes, replacing old panels like federal pacific with modern breaker panels enhances both performance efficiency and safety levels of your power system.

How to Install a Tesla Wall Charger: The Ultimate Guide

There are now over 2 million electric vehicles in the United States.

The company that has gained a stranglehold on the electric car market in recent years is Tesla. Tesla has loyal fans waiting eagerly for every new release and has created a devoted fanbase.

If you run a commercial space, it’s likely that some of your employees have electric vehicles. They will need somewhere to charge them while they work.

Do you know how to install a Tesla wall charger? Keep reading to discover everything you need to know about installing a Tesla charger.

How to Install a Tesla Wall Charger

Putting a Tesla wall connecter up to charge vehicles in the workplace isn’t the most straightforward job in the world.

Jobs like this are often best left to the professionals. Let’s take a look at some of the steps that they would take when installing a commercial EV charger.

Step 1: Gather the Necessary Tools and Materials

Before embarking on an EV charger installation journey, it’s important to gather all the tools and materials that are needed for the job.

These include a screwdriver, pliers, wire stripper, voltage tester, conduit pipes, circuit breaker, appropriate wiring, and of course, the Tesla Wall Charger itself.

Having everything prepared in advance will make the process smoother and more efficient.

Step 2: Choose the Right Location

Selecting the ideal location for the Tesla charger is crucial.

It should be close enough to where your employees usually park their Teslas or EVs so that the charging cable comfortably reaches their vehicles.

Additionally, ensure the chosen spot provides easy access to your property’s electrical panel. This strategic placement will minimize the length of wiring required, simplifying the installation process.

Step 3: Check Your Electrical Panel

Safety should always be a top priority when dealing with electrical installations. A certified electrician will evaluate your electrical panel’s capacity before they start the job.

This step ensures that your panel can handle the increased load without any risks of overloading. Safety first!

You may be tempted to do this yourself. But it can’t be stressed enough that if you’re not fully knowledgeable and comfortable working with electronics, then you shouldn’t. There are teams of experts out there who can handle these jobs for you.

Step 4: Install the Circuit Breaker

The circuit breaker is the heart of the Tesla Wall Charger setup. To power the charger, the electrician will need to install a dedicated breaker in your electrical panel.

They will begin by switching off the main power supply. A professional will be certain that the breaker’s amperage matches the charger’s requirements to ensure safe and efficient charging.

Once again, do not attempt this step yourself if you are not knowledgeable enough.

Step 5: Run the Wiring

With the breaker in place, it’s time to carefully run the wiring from the panel to the chosen location for the Tesla Wall Charger.

The electrician will use conduit pipes to protect the wiring from any potential damage and maintain a tidy appearance. Properly securing the conduit pipes along the route is essential for both safety and aesthetics.

Step 6: Mount the Tesla Wall Charger

Using the provided mounting template, the electrician will mark the precise locations for the mounting holes on the wall. They will then carefully secure the Tesla Wall Charger in position using the appropriate screws and anchors.

Ensuring a secure mount guarantees the longevity of your charger and prevents any unfortunate accidents.

Step 7: Connect the Wiring

Now comes the moment to connect the wiring to the Tesla Wall Charger. The electrician will ensure that every connection is tight and secure.

They will utilize wire strippers to remove the necessary insulation from the wires and connect them according to the provided diagram.

A meticulous approach at this stage guarantees the charger’s optimal functionality and safety.

Step 8: Test the Charger

Before considering the installation complete, the electrician will conduct a thorough test of the Tesla Wall Charger. They will turn the main power supply back on and use a voltage tester to confirm that the charger is receiving power as expected.

Finally, they’ll connect your Tesla to the charger and verify that it begins charging. This final test reassures you that everything is operating correctly.

Why You Should Get a Tesla Wall Charger

Having a Tesla Wall Charger has its perks beyond just convenient charging. One big plus is how quickly it charges the car. Unlike regular outlets that are slow, this charger speeds things up, so people spend less time waiting.

Plus, the charger takes care of the cars’ batteries. It’s smart and makes sure that batteries don’t get overcharged or strained. This care can help people’s batteries last longer, which is a great bonus.

Future-Ready Charging

Tech keeps changing, and so do electric vehicles and chargers. The good news is your Tesla Wall Charger is ready for the future.

Some models can update themselves wirelessly, so you’re never behind. This means your charger stays useful as new EV tech comes out.

Getting the installation in early will benefit your business. Electric vehicles are only going to get more popular and so your employees will want somewhere to charge them.

Choosing Green Transportation

Installing a Tesla Wall Charger isn’t just about convenience. It’s also about being eco-friendly. Electric cars cut down on pollution and fossil fuel use.

Allowing your employees to charge a Tesla at work is like joining a green movement right from your office. You’re not just allowing them to charge their car; you’re helping the planet too.

Not Everyone Knows How to Install Tesla Wall Charger: Get Help Today

Embracing electric vehicles is not only environmentally friendly but also contributes to a more sustainable future.

Installing a Tesla Wall Charger at your commercial property empowers you to be part of this positive change, making charging your employees’ vehicles convenient, efficient, and hassle-free.

But reading how to install a Tesla Wall Charger and actually doing it are two very different things. Huston Electric is here to help.

Have a chat with us today to find out how we can help you install EV chargers at your business property.

The Essentials: What to Expect from Qualified Commercial Electricians

The total U.S. electricity consumption in 2022 skyrocketed to an unprecedented 4.05 trillion kWh. A staggering 14-fold increase from the modest power utilization of 1950.

As our reliance on electricity intensifies, so does the need for skilled professionals who can navigate this intricate web of energy. There’s a growing demand for qualified electricians in every sector. Whether you own a small business or run a large corporation, reliable professionals are essential for handling your electrical needs.

But what exactly can you expect from qualified commercial electricians? What electrical services do they offer, and how can they help you achieve your goals?

This guide will answer these questions and more. Here are the essentials you should know about qualified commercial electricians.

Accessibility for Timely Support

When you hire local commercial electricians, you’re getting experts who know your area well. They understand the local regulations that govern electrical work. This includes building codes, processes to get permits, and the licenses needed for electrical jobs.

Being close by also means they can come quickly when you need them. These electricians can bring teams to install things, do upkeep, and fix emergencies fast. This is important because any business disruptions could mean losing money.

It’s estimated that electrical problems cause around 28,000 fires yearly. Working with local electricians means that you can limit the damage. The best offer 24/7 services, ensuring you get your power back as soon as possible.

Wide Range of Electrical Services

Professional commercial electricians can manage a wide range of electrical tasks for businesses. They offer services from basic repairs to advanced installations.

Electrical Design and Installation

An expert can help you plan and execute the electrical layout and wiring of your new or renovated commercial space. They can also advise you on the best types of electrical systems and devices for your specific business needs and goals.

Electrical Maintenance and Repair

Electricians inspect and test your electrical systems and equipment regularly. They help identify any problems and fix them. You can also rely on them for preventative maintenance services to avoid costly breakdowns in the future.

Electrical Upgrades and Improvements

Electricians play a vital role in ensuring your systems and devices are efficient. They provide ongoing upgrades, ensuring you can always rely on your system. They also customize the upgrades to your needs and preferences.

Electrical Emergency Service

Commercial electricians can respond to electrical emergencies and restore your power as soon as possible. They are available 24/7 for your convenience and peace of mind.

Safety and Compliance

Safety is incredibly important when dealing with electricity. Mishandling it can lead to injuries, damages, and even fatalities. Working with qualified commercial electricians reduces these risks.

They have the training to handle electrical work safely and effectively. Moreover, they are certified and insured. This gives you peace of mind that they adhere to best practices to prevent accidents.

Electrical service providers also have an intimate knowledge of relevant regulations. This includes local, state and federal codes that govern electrical systems.

They can help you obtain the right permits, licenses, and approvals for your projects. You can also rely on them to ensure your system is always in good condition.

Efficiency and Minimized Downtime

Another benefit of professional commercial electricians is their ability to improve efficiency and reduce downtime. Electrical systems are crucial in ensuring the smooth operation of a business. Any outage or malfunction can reduce productivity, leading to loss of money.

Local commercial electricians provide a fast and reliable service. This helps prevent the above issues. They can also help optimize your system for maximum performance.

A professional can advise you on the best solutions for:

Power quality

Regulating voltage

Load capacity

They can even install energy-efficient devices to reduce your costs.

Cutting-Edge Technology and Innovation

The field of electricity is always evolving, with new equipment, methods, and innovations. Continuing education is essential for electricians to keep delivering their best work. It’s a lifelong process of acquiring new skills and knowledge.

As a result, they can adapt to your evolving needs. Electricians can help you take advantage of evolving technologies, such as:

Smart lighting controls

Solar panels

Electric vehicle charging stations

High-efficiency LED lighting

This can be incredibly beneficial for your business. It can help you cut costs and achieve your sustainability goals.

Reliable Electric Repair Services

Qualified commercial electricians are not only good at installing new electrical systems. They are also great at repairing existing ones. They have the diagnostic skills and equipment to identify and fix any electrical issue quickly and accurately, such as:

Faulty wiring or outlets

Damaged or blown fuses or circuit breakers

Malfunctioning or flickering lights

Tripping or buzzing switches

Broken or loose connections

Overheating or sparking devices

Commercial electricians can also provide preventive maintenance and services. This can help ensure your system is always functional and prevent costly failures.

Partnership for Long-Term Success

Experienced commercial electricians also play a vital role in your long-term success. As skilled service providers, they build relationships based on trust, respect, and communication.

They are always available to respond to your needs and concerns. Moreover, electricians are flexible and easily adapt to your evolving needs.

Their extensive training allows them to identify and fix problems efficiently. This minimizes downtime and disruptions.

Their commitment extends beyond a single project. The best electricians should support your ongoing electrical needs. They provide valuable advice and feedback to help you achieve your goals.

You also benefit from warranties, guarantees, and follow-ups to ensure your peace of mind. As a result, you will save big on your electrical repairs, installations, and projects in the long run.

Your Go-to Commercial Electricians

If you’re looking for qualified commercial electricians, look no further than Huston Electric. We take pride in installing, repairing, and maintaining commercial electrical systems in Indiana.

Our team comprises of experienced and certified electricians who can handle any project. We also offer competitive pricing, free estimates, and 24/7 emergency service.

Don’t settle for less than the best. Contact us today to schedule a consultation and discuss your needs. We are here to serve you with the utmost respect and professionalism.